| Standard Configuration |

Optional Configuration |

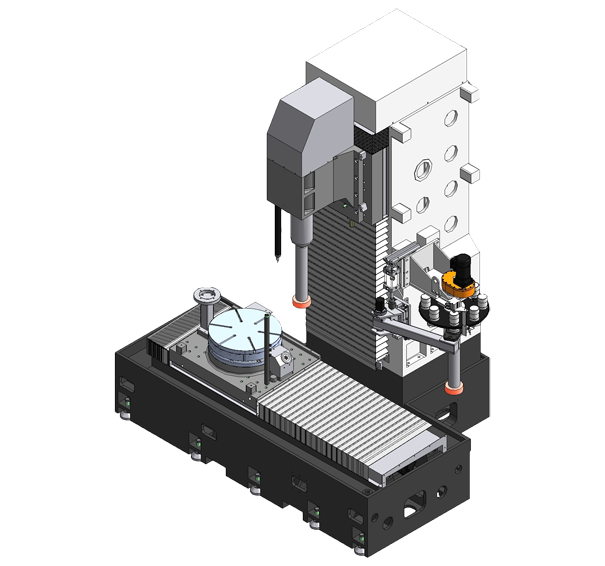

| Controller: Mitsubishi M80 |

Mitsubishi M80 iGrind Conversational Software |

| Grinding Wheel Spindle (HSK-A100 internal coolant included) |

Permanent Magnet 600mm (includes 8 magnetic guides) |

| NSK Ball Screws (1 set, made in Japan) |

Electromagnetic Coolant Filtration System with Paper Filter and Cooler |

| Automatic Lubrication System |

Hydraulic Separator 120L/min |

| HSK Grinding Wheel Spindle x2 |

Coolant Temperature Control System |

| ATC Tool Changer Magazine (6/8 tool capacity) |

HSK-A100 Grinding Wheel Spindle |

| Work Spindle 600DD Direct Drive Motor (5.5kW) |

Oil Mist Collection System |

| Closed-loop X-axis MP Encoder (Mitsubishi, 0.05μm) |

Dresser Seat |

| Motor Heat Exchanger |

Power Sensor for Grinding Wheel Impact Prevention (Power Detection) |

| Circular Workpiece Fixture Groove |

Renishaw LP2 Probe System for Grinding and Measuring (including Comparator) |

| Coolant Adjustment Pad |

Z-axis Optical Scale Renishaw with 0.05μm Resolution |

| Adjustment Tools and Tool Box |

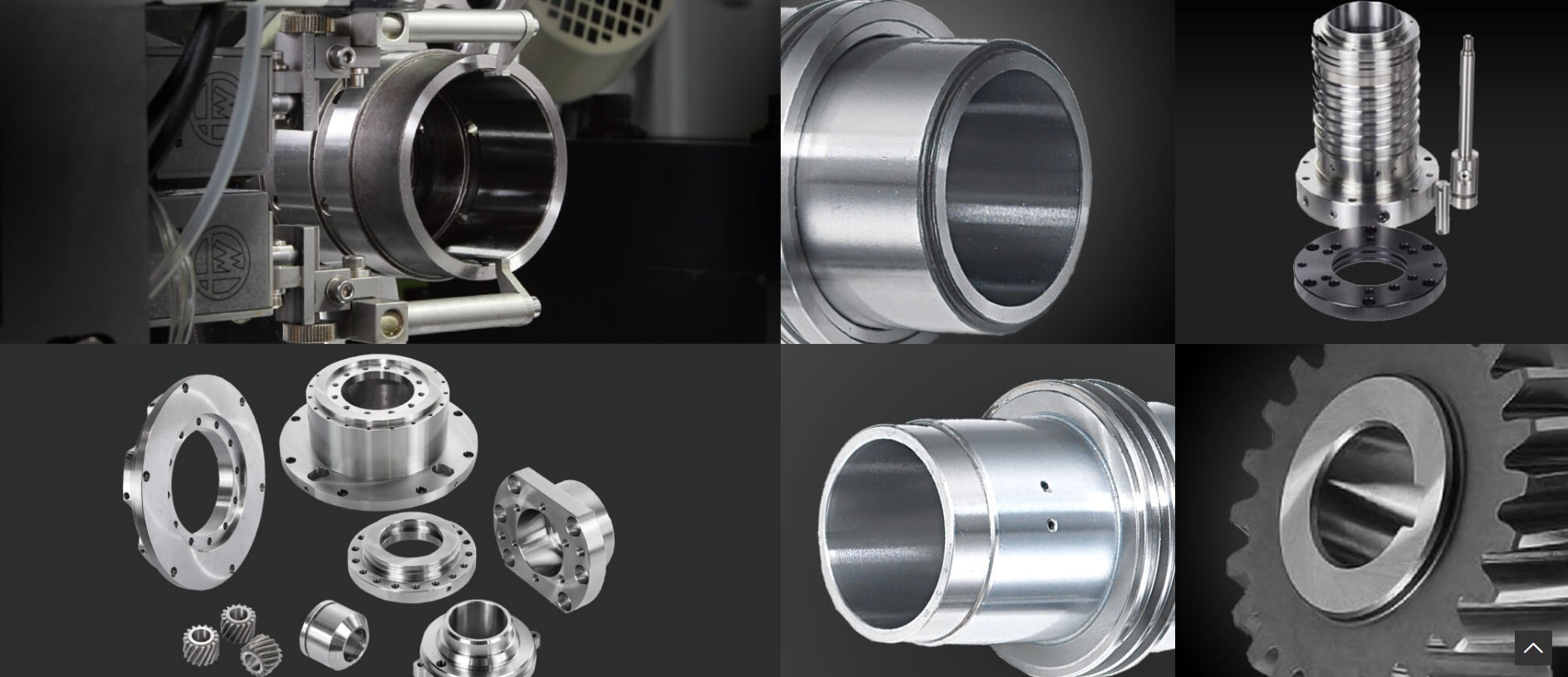

Special Clamping Fixture (Jigs) |

| Full Sheet Metal Enclosure |

Deep Hole Grinding Wheel Spindle |

| Three-Point Adjustment Seat x1 |

|

| Tri-color Indicator Light |

|

| Machine Work Area LED Lighting |

|

| Operation Manual and Spare Parts List |

|

| Circuit Diagram |

|